Everyone is familiar with LED lights. It is the current mainstream lighting product. It has the advantages of high efficiency, long life, energy-saving, environmental protection, safety and reliability, and is highly favored by consumers. Nowadays, there are many brands of LED lamps on the market. Consumers don’t know how to choose, and they don’t know how to judge their quality. This article will introduce the process of LED lights from raw material production to finished products, and explain the characteristics of each part of the LED step by step. After reading it, you will know how to judge the quality of the LED lights.

- LED chip

The core of LED light is the LED chip, which is also the most critical place for the quality of LED lights. A good chip has the following advantages:

1) High luminous efficiency. 1W power consumption is considered to be 130lm light, and 1W power consumption only emits 60lm light.

2) Lower light decay, the LED chip will inevitably age during the light-emitting process, and then light decay. Generally, the lamp will be darker than the first one after a while. Lower luminous decay can ensure a longer life.

3) With higher junction temperature, the light decay of the LED gradually increases with the rise of temperature. Once the internal temperature of the LED exceeds the junction temperature, the light decay will increase in a straight line. The boundary temperature of American CREE chips can reach 120 degrees, and the temperature of Taiwan factories is generally 80 degrees.

High luminous efficiency will reduce heat generation, and lower heat generation can reduce light decay, and higher junction temperature will reduce the requirements of the radiator. Choosing high-end chips is the first step for good LED lamps.

2. Package

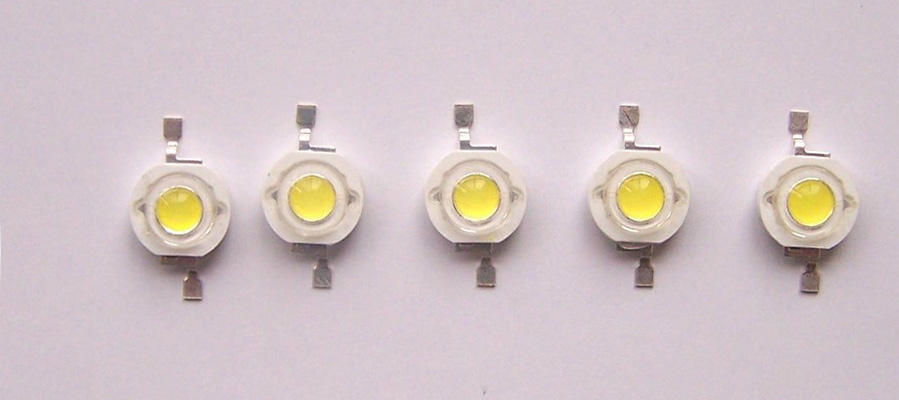

The LED chip is quite small, not 1mm, can not be directly soldered on the circuit board, and it will quickly oxidize and be scrapped when exposed to air at high temperature. So we need to package the LED chip on a suitable bracket for our processing and use.

This is a classic imitation lumen packaged lamp beads. This lamp bead is divided into four parts, bracket, chip, connecting wire and phosphor. The lamp beads of other packaging structures include these four parts.

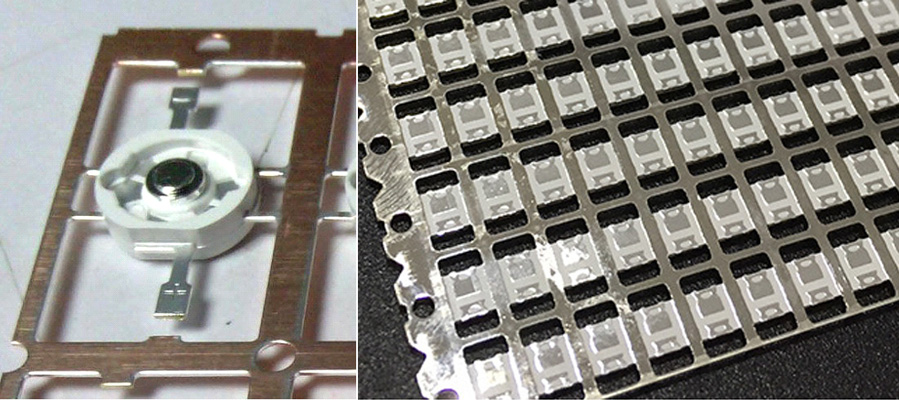

1) Bracket

Our chip less than 1mm is placed in the middle of the bracket. The two ends of the bracket are “-” on one side and “+” on the other side. This is the interface for connecting with the external circuit. The bracket is a shelf that carries the chip and is responsible for conducting the heat emitted by the chip and connecting the chip with an external circuit. There are several kinds of materials for brackets: iron, brass, copper, ceramics, and aluminum. According to the function of the bracket, we can think that the material with the best thermal conductivity is the best bracket material. Red copper is pure copper with the best thermal conductivity. Good, and the most expensive, brass is the second of zinc-copper alloys in thermal conductivity, and iron is the worst. Ceramics and aluminum are generally used to encapsulate COB lamp beads. COB lamp beads are used to encapsulate many chips on support.

2) Chip as mentioned above

3) Connection line

There are four connection points on the chip, two round points and two square points, and wires are required to connect these four points to the bracket. The connection point is very small and requires very thin wires, but can carry a lot of currents. Generally, there are three kinds of materials, gold wire, alloy wire, and copper wire. Gold has very good ductility and stability and is the best material. Alloy wire is the second-best material with silver-gold alloy performance, and copper wire is the worst. In recent years, the introduction of a flip-chip structure can save the connection line.

4) Phosphor

LED chips used for lighting are blue-emitting chips, which emit white light through yellow phosphors. The phosphor must be stirred with glue and then dropped onto the surface of the chip. After solidification, the chip is packaged. Poor phosphors are easy to vulcanize and turn black, fade, and swell to de-soldering the gold wire. Good phosphors have good stability. Many chip manufacturers such as CREE, Philips, Osram, and Nichia have their packaging plants.

There are many specifications for packaging. The most used ones are 5050, 2835, 5730, imitation lumen, imitation Sharp, imitation Citizen, imitation CREE, it can be said that the packaging standards are others.

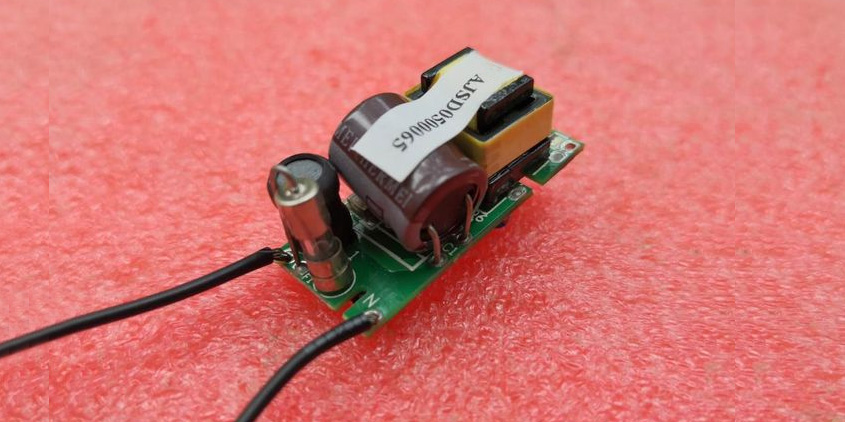

3. Power

A single LED is generally driven by a DC 2.5-3.5V voltage, and our mains power is AC 220V. A transformer is needed in the middle. This transformer is called a power supply in the industry. The power supply is divided into constant voltage source, constant current source, and resistance-capacitance source. Most LED lamps use a constant current source, and only low-voltage LED strips to use a constant voltage source. The production of the power supply is quite simple. The manufacturer of the power management chip provides the plan, and then builds the circuit board according to the plan, buys the accessories, and assembles it. Mingwei is a well-known power supply factory.

- Radiator and shell

Although the luminous efficiency of the LED light source is much higher than that of the U-Si lamp, the current LED cannot convert 100% of the electric energy into light energy, and a considerable part of the electric energy is converted into heat energy. As mentioned above, the life of the LED chip is closely related to the temperature. The heat sink and the housing are the most important parts that determine the temperature of the finished LED lamp. There are many forms of LED heat sinks and housings, and there are many ways to dissipate heat. The materials are aluminum, ceramic, and plastic. The heat dissipation methods include increasing air contact area, diversion, air cooling, water cooling, and phase change.

- Light color

There are several parameters of light color, such as color temperature, CRI, XY coordinates, and spectrum. In fact, all lamps, whether LED lamps, energy-saving lamps or incandescent lamps, have these light-color parameters. We call the color temperature 2700-3200K for warm white (such as the kind of incandescent lamp), 4000-4500K for natural white (such as sunlight), and 6000-6500K for cool white (such as the light of a fluorescent tube). CRI, CRI is highly realistic for color reproduction, and the color authenticity is based on sunlight. Households rarely require this. It is difficult for our naked eyes to judge without comparison without equipment. So look for regular manufacturers or certified products.

When we buy LED lighting products, we can refer to the parameters such as chip, material, luminous efficiency, power supply, heat sink, light color and so on. By understanding the quality and material of LED components, we can judge the quality of LED lighting products. We can also buy suitable LED products.