Scope of application:

used for disinfection of air, the surface of objects, water and other liquids.

UV disinfection lamp and UV disinfector

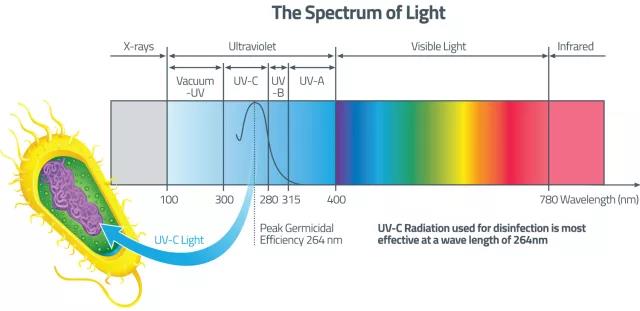

(1) The ultraviolet light used for disinfection is C-wave ultraviolet light, and its wavelength range is 200nm~275nm. The strongest sterilization waveband is 250nm~270nm. The ultraviolet light source used for disinfection must be able to produce a germicidal ultraviolet lamp with an irradiation value that meets the national standard.

(2) For the preparation of ultraviolet disinfection lamps, grade quartz glass tubes or materials with an ultraviolet transmittance not lower than quartz glass should be used to obtain satisfactory ultraviolet radiation intensity.

(3) The ultraviolet disinfection lamp can be equipped with a reflector made of materials with a high ultraviolet reflection coefficient (such as a polished aluminum plate)

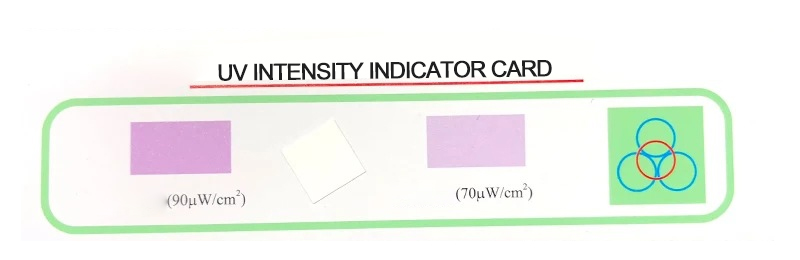

(4) When the voltage of the ultraviolet lamp used for disinfection is 220V, the relative humidity of the environment is 60%, and the temperature is 20℃, the radiated 253.7nm ultraviolet intensity (intensity in use) shall not be less than 70μW/cm2 (using plane measurement) )

(5) The ultraviolet intensity meter used must be calibrated and within the validity period; the ultraviolet intensity monitoring indicator card used should obtain a sanitary license and be used within the validity period).

(6) The radiation intensity of the ultraviolet lamp gradually decreases during use, so the intensity of disinfection ultraviolet light should be measured regularly, and once it drops below the required intensity, it should be replaced in time.

(7) The service life of the ultraviolet disinfection lamp, that is, the time to reduce the intensity of the new lamp to 70μW/cm2 (power≥30W), or the time to reduce to 70% of the original intensity of the new lamp (power<30W), should not be low In 1000h. The UV lamp manufacturer should provide the actual service life.

(8) At present, there are the following types of ultraviolet disinfection lamps in use in my country:

1) Ordinary straight tube hot cathode low-pressure mercury ultraviolet disinfection lamp: The lamp tube is made of quartz glass or other glass with high ultraviolet transmittance, and the power is 40W, 30W, 20W, 15W, etc. The intensity of 253.7nm ultraviolet radiation (measured at a distance of 1m, without reflector) from the factory new lamp is: power>30W lamp, ≥90μW/cm2; power>20W lamp, ≥60μW/cm2; power 15W lamp, ≥20μW /cm2. Since this kind of lamp radiates 253.7nm ultraviolet light, it also radiates part of 184.9nm ultraviolet light, so it can produce ozone.

2) High-intensity ultraviolet disinfection lamp: the intensity of 253.7nm ultraviolet radiation (measured at a vertical distance of 1m from the center of the tube) is: power 30W lamp, >170μW/cm2; 11W lamp, >40μW/cm2.

3) Low-ozone ultraviolet disinfection lamp: It is also a hot-cathode low-pressure mercury lamp, which can be straight tube type of H-type. Due to the special process and tube material, the ozone output is very low, and the ozone output is required to be <1mg/h.

4) High-ozone ultraviolet disinfection lamp: Due to the adoption of a special process, this kind of lamp produces a relatively large proportion of ultraviolet rays with a wavelength of 184.9nm, so the ozone output is relatively large.

(9) Ultraviolet sterilizer:

1) Ultraviolet air sterilizer: It is made of a low-ozone ultraviolet germicidal lamp, which can be used for indoor air disinfection under human conditions.

2) Ultraviolet surface sterilizer: It is made of a low-ozone high-intensity ultraviolet germicidal lamp, so that it can quickly reach a satisfactory disinfection effect.

3) Ultraviolet disinfection box: It is made of a high-ozone high-intensity ultraviolet germicidal lamp or straight tube high-ozone ultraviolet lamp. On the one hand, it uses the synergistic sterilization effect of ultraviolet rays and ozone, and on the other hand, it uses ozone to disinfect the parts that cannot be irradiated by ultraviolet rays.

Scope of application and conditions of use

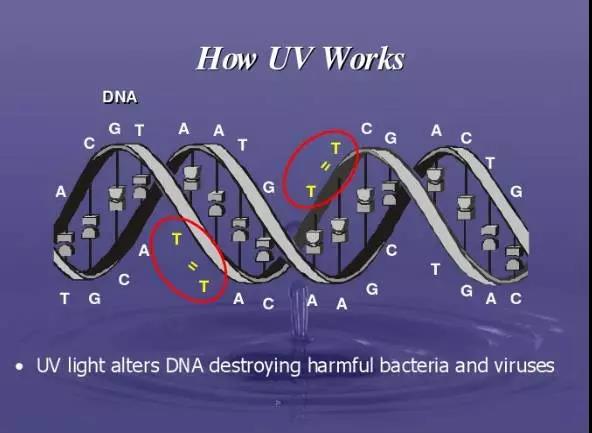

(1) Ultraviolet rays can kill various microorganisms, including bacterial propagules, spores, mycobacteria, viruses, fungi, rickettsiae and mycoplasma, etc. All surfaces contaminated by the above microorganisms, water and air can be disinfected by ultraviolet rays.

(2) Ultraviolet radiation has low energy and weak penetrating power, and can only kill the directly irradiated microorganisms. Therefore, the disinfected part must be fully exposed to ultraviolet rays during disinfection.

(3) When using ultraviolet rays to disinfect rough surfaces such as paper and fabrics, the irradiation time should be extended appropriately, and both sides should be irradiated.

(4) The suitable temperature range for ultraviolet disinfection is 20℃~40℃. Too high or low temperature will affect the disinfection effect. The disinfection time can be extended appropriately. When used for air disinfection, the relative humidity of the disinfection environment should be lower than 80%. Otherwise the irradiation time should be extended appropriately.

(5) When using ultraviolet rays to kill microorganisms protected by organic matter, the radiation dose should be increased. Suspended particles in the air and water can also affect the disinfection effect.

Use and disinfection method

(1) Disinfection of the surface of the article:

1) Irradiation method: It is best to use a portable ultraviolet sterilizer to move and irradiate at a short distance, or to use a suspended ultraviolet lamp to irradiate. Small items can be irradiated in the ultraviolet disinfection box.

2) Irradiation dose and time: Different types of microorganisms have different sensitivity to ultraviolet rays. When using ultraviolet rays for disinfection, the irradiation dose must be used to reach the irradiation dose required to kill the target microorganisms.

When killing general bacterial propagules, the radiation dose should reach 10000μW.s/cm2;

It should reach 100000μW.s/cm2 when killing bacterial spores;

The resistance of viruses to ultraviolet rays is between that of bacterial propagules and spores;

The resistance of fungal spores is stronger than that of bacterial spores, sometimes it needs to be irradiated to 600 000μW.s/cm2, but the resistance of pathogenic fungi to ultraviolet rays is generally weaker than that of bacterial spores;

When the target microorganism for disinfection is unknown, the irradiation dose should not be less than 100 000μW.s/cm2.

The irradiation dose is the product of the irradiation intensity and the irradiation time of the ultraviolet lamp used at the surface of the irradiated article. Therefore, according to the irradiation intensity of the ultraviolet light source, the required irradiation time can be calculated. For example, using an ultraviolet surface sterilizer with an irradiation intensity of 70μW/cm2 to irradiate the surface of an object at close range, and the selected irradiation dose is 100000μW.s/cm2 (to kill bacterial spores), the irradiation time is:

100 000μW.s/cm2 ÷ 70μW/cm2 = 1429 s ÷ 60s ≌ 24min.

This time plus a certain safety time can be used as a reference basis for the disinfection time of the UV lamp of the transfer window.

(2) Disinfection of indoor air:

1) Indirect irradiation method: the first choice is a high-intensity ultraviolet air sterilizer, which not only has a reliable disinfection effect, but also can be used when people are moving indoors. Generally, the disinfection can be qualified after 30 minutes of starting the disinfection.

2) Direct irradiation method: Under unmanned conditions indoors, direct irradiation with UV lamps suspended or mobile can be adopted. When using indoor suspended UV disinfection, the number of indoor UV disinfection lamps (30W UV lamp, intensity at 1.0m> 70μW/cm2) is an average of not less than 1.5W per m3, and the irradiation time is not less than 30min.

(3) The disinfection of water and other liquids can be carried out by internal or external water irradiation. When using internal water irradiation, the ultraviolet light source should be equipped with a quartz glass protective cover. No matter what method is adopted, the thickness of the water layer should be less than 2cm, the water flow speed is determined according to the intensity of the ultraviolet light source. After disinfection, the water must meet national standards.

Precautions

(1) Appendix I of the 2010 edition of the “Guidelines for Quality Management of Pharmaceutical Production”, “Sterile Drugs” stipulates that ultraviolet disinfection shall not be used instead of chemical disinfection.

(2) During use, the surface of the UV lamp should be kept clean. Generally, wipe it with an alcohol cotton ball once every two weeks. When dust or oil stains are found on the surface of the lamp, it should be wiped at any time.

(3) When using ultraviolet light to disinfect indoor air, the room should be kept clean and dry to reduce dust and water mist. The temperature should be lower than 20℃ or higher than 40℃, and the relative humidity should be longer than 60%. The irradiation time should be appropriately extended.

(4) When using ultraviolet rays to disinfect the surface of an article, the irradiated surface should be directly irradiated by ultraviolet rays, and a sufficient radiation dose should be achieved.

(5) Do not irradiate people with UV light sources to avoid damage.

(6) The UV intensity meter is calibrated at least once a year.